"One belt, one road" initiative is being actively promoted by the profiles of Thailand conch section project. The project is accelerating the internationalization of the company. After the Burma project, it has invested second overseas projects. The project is located in the middle Industrial Park of Layong province Thailand, and plans to produce 30 thousand tons of aluminum products per year. Since the commencement in April 2019, in the face of many difficulties such as the rampant overseas epidemic, the inability of technicians from equipment manufacturers to enter the site on time, lack of experience in overseas project construction, cultural differences and so on, conch profile expatriate cadres and employees have come to this land without hesitation to promote the project construction and operation with their own efforts and sweat. At present, the civil works of the Thai project have been completed, the doors and windows, aluminum extrusion and spraying production lines have been commissioned, the installation of oxidation and casting equipment has been steadily promoted, and the overall equipment installation and commissioning progress has reached 90%. The project is planned to fully realize trial production in the second half of the year.

Only when it is difficult can we show courage. During the construction and operation of the project in Thailand, there are such a group of people who stay away from their relatives and stick to their posts. Among the first 21 comrades of the project team, 19 comrades have been fighting in Thailand for more than one year. When the epidemic in Thailand is becoming more and more serious this year, 37 dispatched personnel successively "retrograde" to Thailand to participate in the project construction in the later stage of the project, They practiced the original intention and mission of conch people in foreign countries with practical actions.

Panorama of Thailand project

In June this year, the fifth batch of personnel to Thailand were ready to go to Thailand

Hu Jian, executive deputy general manager of Thailand company, an old Party member with 24 years of Party age and an old comrade who has joined conch for 40 years, has participated in the construction of 8 base projects of the joint stock company. In September 2019, Hu Jian received the notice of going to Thailand to work on the project. He did not raise any difficulties to the organization and went to Thailand to take on a new mission. Up to now, the 58 year old comrade has been fighting for more than 690 days in Thailand.

The construction of overseas projects is quite different from that of domestic mature profile projects. The complexity of project approval and construction, engineering construction and many supporting facilities is far beyond imagination. After arriving at the site, this veteran who has been on the battlefield for a long time keeps a close eye on the construction progress during the day, and works at least 25000 steps a day under the outdoor high temperature of 30 or 40 degrees all year round, In the evening, the drawings are examined point by point to ensure the construction progress and quality. In June 2020, the main works of the Thai project will be fully completed. Especially during the installation of 115kv substation and LNG gas station, affected by the epidemic situation, there was a serious shortage of civil construction personnel. In order to ensure the progress, he was not only the commander, but also the forklift and porter. He led everyone to work in shifts and fight continuously. The concrete base several meters high was completed in one week, ensuring the effective connection of the equipment after arrival. After two months of hard work, The substation and gas station were successfully installed.

Comrade Hu Jian guided the equipment installation on site

In April of this year, the third wave of COVID-19 broke out in Thailand and spread all over Thailand. The Thailand project was also in the critical stage of transformation from infrastructure to commissioning. Epidemic prevention and control, market expansion, civil engineering termination, equipment commissioning and installation, production protection and "five big mountains" were pressing on the shoulders of the project team. Comrade Hu Jian was the first to bear the brunt of the "pioneers". We will move forward bravely and fully promote the construction and operation of the project. Since May, the Thai project has gradually shifted to the commissioning and operation stage. The commissioning of the remaining extrusion lines has been completed in June, the installation of the sewage treatment station has been completed in July, the equipment installation in the oxidation workshop has entered the final stage, the furnace building and some electrical installation have been completed by melting and casting, and the comprehensive management and commissioning stage will be entered in August. From January to July, Thailand's local market expansion achieved 200 tons of local orders such as JINHAIYANG, ATG and UAI, and foreign trade achieved 125 tons of orders such as kastin in Hangzhou and Jiuxin building doors and windows in Cambodia, realizing 220 tons of sales and initial results in sales market expansion.

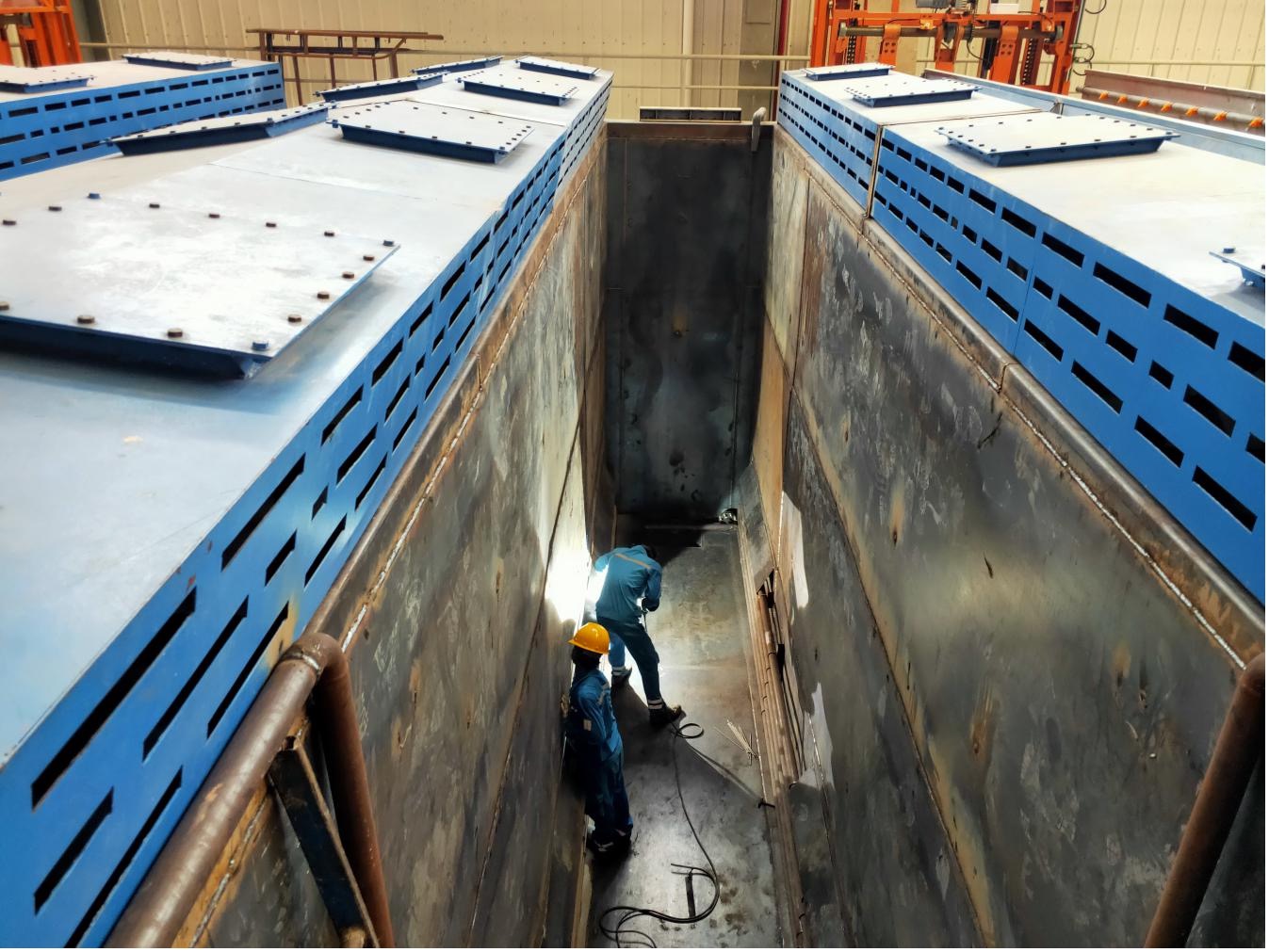

Installation in oxidation workshop

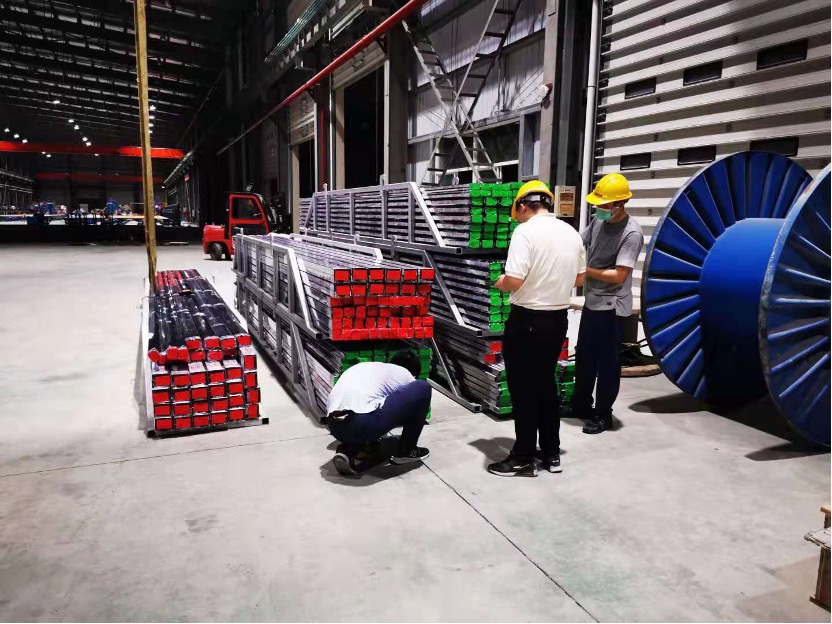

Sales order check shipment

115 substation closing and power transmission

In August 2018, Comrade Wang Zhoujin went to Thailand alone to be responsible for the handling of early-stage warrants for Thai projects. Originally a little shy, he overcame the language barrier and "brazenly" visited local Chinese enterprises, park offices and relevant government departments during the day. With a pious "pupil" mentality and a notebook, he kept asking for advice and asking about the requirements of policies, laws and regulations related to investment in Thailand. After returning at night, he checked the information on the Internet and studied it repeatedly to fully master the project approval procedures, With his efforts, the company has successfully obtained DBD registration certificate, boi certificate, project title deed, land use permit, IEE environmental assessment, building permit, building acceptance and other certificates. Among them, IEE EIA approval is the key to the commencement of construction, covering a wide range and taking a long time to review. In the face of difficult problems such as the differences between Chinese and Thai design, environmental protection standards and drawing standards, he clarified his ideas, took the initiative to connect, strengthened the exchange and communication between EIA units and government officials, and finally passed the approval of Thailand industry authority after six months of hard work (Ieat) Bangkok headquarters reviewed and successfully obtained IEE EIA approval, which laid a foundation for the start-up of the project.

Wang Zhoujin handles IEE EIA approval (first from the right)

After the domestic epidemic broke out in 2020, the Thai company set up a leading group for epidemic prevention and control. As the director of the epidemic prevention and control office, he timely formulated the emergency plan for epidemic prevention and control, made a good reserve of epidemic prevention materials, launched all the personnel of the project team to "go shopping" and urgently purchased 50000 masks to support China. At present, Thailand is in the third wave of epidemic outbreak, with more than 15000 newly confirmed cases in Japan. He fully learned from the successful experience of domestic epidemic prevention and control. While paying attention to the normalization of epidemic prevention and control, combined with the local actual situation of Thailand, he actively guided Thai employees to sign a voluntary vaccination commitment, and completed the vaccine appointment of Thai employees through multi-party coordination; At the same time, actively carry out the publicity and implementation training of employee epidemic prevention and control, strengthen daily supervision, sign the "joint insurance" responsibility letter and employee commitment letter, and send self-protection warning information every day, so as to achieve neither ideological paralysis nor excessive panic, respond scientifically in the whole process, and effectively close the company's epidemic defense line. When a large number of confirmed cases have been exposed by surrounding enterprises, Thailand building materials projects still maintain the suspected and confirmed "0" record!

In May this year, the whole staff of the Thai company tested nucleic acid

Li Jie won the first "conch craftsman" and the honorary title of labor model of the group in 2020. In the face of honor, he did not look back too much, but volunteered to participate in the construction of aluminum project in Thailand, and successively assisted in the general drawing planning and design, equipment configuration and selection of Thai project. Among them, aluminum oxidation equipment and melting and casting equipment were configured for the first time, with complex process and great technical difficulty. For his tireless pursuit of technology, he made every effort to collect relevant material data, continuously studied and studied, communicated with the Design Institute, equipment manufacturers and external consultants for hundreds of times, and finally integrated various advantageous resources to complete the preparation of equipment technical scheme and equipment purchase. During the installation and commissioning of the spraying process, because the personnel of domestic equipment manufacturers were blocked from going to Thailand during the epidemic, he communicated with the manufacturers for many times, repeatedly confirmed the drawings and technical parameters, and led the personnel of the project team from the splicing of a square steel and an angle iron to the fixed-point installation and electrical wiring of the equipment. He dared not leave the site for a moment for fear of making some mistakes, Due to continuous combat, like other comrades in the project team, his eyes are often full of blood. After working overtime for more than a month, the linkage commissioning of the whole spraying line was completed by the end of September 2020!

Li Jie checks the equipment installation on site (middle)

At present, the extrusion and spraying lines have been put into commissioning and operation, and the installation of oxidation and casting equipment has reached the key final commissioning stage. As the director of equipment preservation department and the head of aluminum branch, he is fully engaged in the work of equipment installation and commissioning and production guarantee and supply line operation. Facing multiple difficulties such as the lack of mature technicians and the great difficulty of management of Thai employees, Gradually build the organizational structure of the branch plant, improve the production organization process, sort out the difficult problems affecting the production and supply assurance process, such as die commissioning, extrusion of special shapes, spraying shrinkage and so on, and finally overcome one technical problem after another, complete the production of 145 tons of aluminum, and achieve the effect of running in the machine, training the team and improving skills, It has laid a solid foundation for the full transfer to trial production and operation.

Stable operation of spraying production line

Door and window project is an important carrier to expand overseas market share, ensure project construction and promote the company's overseas layout. In November 2019, Thailand's door and window project took the lead in putting into operation. In the face of the "zero" foundation of door and window production, slow mastery of skills and difficult language communication of new Thai employees, in order to ensure that the door and window project can give full play to its production capacity and produce benefits quickly, Zhang Chuanbin, deputy factory director of the door and window branch, led them to do it by themselves first. They watched it, trained and produced at the same time, strengthened communication and exchange at ordinary times, and timely understood the ideological trends of employees on the post, Improve working methods and communicate with Thai people's thinking, so that several "0 basic" Thai employees can gradually get started. In 2020, the company will produce and sell 13300 square meters of doors and windows, successfully achieve profitability, and achieve the expected goal of effective production.

Installation of doors and windows led by Zhang Chuanbin (first from left)

Since there are no large-scale development projects in Thailand, there are few projects with a single project door and window area of more than 2000 square meters. Since this year, the epidemic situation in Thailand has made it very difficult to expand the market and ensure production and supply. Zhang Chuanbin often worked with the sales department to find strategies, strengthen the maintenance of old customers, actively expand new customers, and obtained 8 project orders such as Dongju and Zhongce phase IV plant. From January to July, the production and sales of doors and windows was 9052 m2, with a year-on-year increase of 5514 m2, continuing to maintain a good growth momentum.

"From 0 to 1, this is a process. Although there is a lot of pressure, as long as we have confidence and perseverance, there will be no bad things in conch," Comrade Zhang Chuanbin always said in the face of difficulties.

Xue Jianfeng, deputy director of the sales department, went to Thailand in March 2019 to participate in the project construction in Thailand and was responsible for the market construction. The market is the lifeline of the enterprise. As a marketing veteran with 16 years of sales experience, he is well aware of the great responsibility and the great difference between overseas market development and domestic market development. He overcame the language barrier and entered the market alone while strengthening local sales market research, While combing the construction of market system, we did a good job in market expansion in three market directions of Thailand, Europe, America and ASEAN in accordance with the three directions of "improving product positioning, building marketing channels and enhancing effective system construction". During this period, we visited more than 110 provinces and counties in Thailand to collect the information of nearly 600 sales customers of various building materials, so as to accumulate potential customer base for market expansion, Over the past three years, the company has achieved a total sales volume of 3767 tons, realizing a breakthrough in the Thai market from scratch.

Since this year, third waves of COVID-19 have broken out in Thailand. He has led Chinese and local dispatched personnel with local marketing personnel to expand the market by telephone, WeChat and other online contact customers. While maintaining old customers stably, the company has vigorously expanded new users. At present, the Thai company has achieved 38 cooperative customers, including nearly 30 new customers since the establishment of the plant; Under the guidance of professional departments and offices, strengthen the information collection of potential foreign trade channel customers and follow-up of intended customers, focus on carrying out capacity replacement and order cooperation negotiations of foreign trade enterprises, establish contacts with Hangzhou castin company, Vic SRL of Italy, MPG of the United States and other aluminum foreign border trade customers, actively promote aluminum import and export cooperation, and lay a market foundation for the full production of the company.

"The more we are overseas, the more we need to strengthen risk control. We should establish and improve the internal control system according to local conditions under the framework of joint-stock company system and in combination with the actual situation of Thailand, so as to escort the project construction and company operation," said Zhang Wenju, deputy chief accountant of Thailand company. Since the implementation of the Thai project, the joint stock company has attached great importance to the system construction and clean practice of overseas companies, and specially organized and held a special meeting on the system construction of Thai companies. Follow up the deployment arrangements of the joint stock company. Under the leadership of Comrade Zhang Wenju, the Thai company had issued about 100 professional systems by the end of June. In order to strengthen the training of Thai employees, he also started to make a simple, visual and easy to operate work manual, regularly organized professional system training and interpretation, and took learning, understanding and implementing the system as an effective starting point for professional management and risk control.

Zhang Wenju carried out training on internal control system

In order to further strengthen overseas asset management, standardize operation and management behavior and do a good job in overseas integrity prevention and control, as the leader of the company's supervision team, Comrade Zhang Wenju attaches great importance to the important role of audit supervision in the supervision of overseas enterprises, focusing on standardizing material procurement management, strengthening capital management and controlling expenses, Regularly supervise and inspect the company's various economic and business behaviors, and continuously strengthen the integrity education of overseas dispatched personnel. On the basis of the monthly routine life meeting, an integrity training meeting for dispatched personnel is added every month to further strengthen the education and guidance of post responsibilities, professional ethics, work responsibilities, laws, disciplines and regulations, and make more reminders and frequent requirements, Ensure that the dispatched personnel stick to the ideological "fence", draw a clear "red line" of law and discipline, create a good atmosphere of clean air and positive atmosphere, and lay a solid foundation for the full operation and good operation of the project.