In the golden autumn and September harvest season, overseas embarked on a new journey. At 18:18 on September 16, the production of the first batch of qualified finished products of oxidation materials of Thailand company was completed, and the full-automatic oxidation production line was officially put into production and trial operation. Up to now, the doors and windows, spraying and oxidation products of Thailand project have been put into operation and operate well. The company has fully transferred to the trial production and operation stage, taking a solid step for the internationalization strategy and transformation development of the joint-stock company.

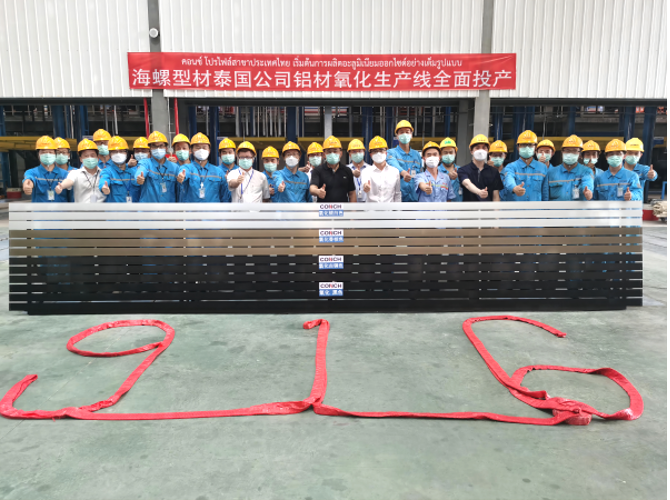

Put into production group photo

Company panorama

Thailand project is one belt, one road, which is actively responding to the layout of the "one belt and one way" layout of the conch industry. It has accelerated the transformation and upgrading of the profile industry. After the Burma project, it has invested second overseas projects. The joint stock company has organized several research teams to conduct a research and inspection of Thailand's economic environment, investment and investment policies, and initially identified the project investment plan. On June 15, 2018, Wan Yong, deputy general manager of the group company, Secretary of the Party committee and chairman of profile Co., Ltd., led a delegation to have in-depth talks with Taizhong Luoyong Industrial Park, reached a consensus on relevant investment matters and officially signed the letter of intent for project investment.

Thailand project signing site

According to the unified deployment of the joint stock company, after the Thai project team entered the site in August 2018, under the guidance of the joint stock company, it self pressurized and took the initiative to overcome language barriers, cultural barriers and other difficulties, creatively carried out work, accelerated the handling of warrants, and successively obtained DBD registration certificate, boi certificate, project land title deed, land use permit, IEE EIA reply and other certificates, It has laid a good foundation for the commencement of the project. After various preparations, the Thai project was officially started on April 22, 2019.

Project commencement and foundation laying ceremony

Make concerted efforts to catch the civil construction progress. After the commencement of the project, the on-site personnel overcome many difficulties such as short construction period, tight time, lack of experience and insufficient skills. With the guidance and assistance of the joint stock company and professional departments, they strictly grasp the construction safety and construction quality, arrange the project time nodes backwards, summon up their energy, meet the difficulties and promote the project construction progress in an orderly manner.

The hoisting of the first girder of the main power house is completed.

official capping of comprehensive office building

Doors and windows were first put into operation to increase benefits. As the first sub project of the project, the door and window branch took the lead in starting construction. All departments of the company worked overtime to plan and implement the equipment tax-free operation, personnel allocation, equipment installation and other work in advance, and took advantage of the commissioning opportunity of the equipment manufacturer to organize the training of new personnel to help Thai employees master their manufacturing skills. On October 28, 2019, the door and window branch plant was put into operation in only 6 months, opening a new prelude to the project operation in Thailand. Up to now, the company has produced and sold 23000 m2 of doors and windows, and realized a profit of * * million yuan.

The door and window branch is put into operation first

We will spare no effort to prevent and control the epidemic. In 2020, COVID-19 suddenly broke out, and was in the critical period of project construction and equipment delivery. In the face of the outbreak of its sudden outbreak, the Thailand project team take time for granted, and respond calmly. On the one hand, we must strictly implement the deployment requirements of the group and joint stock companies, and set up a epidemic prevention and control group quickly, and formulate contingency plans in light of Thailand's reality. Continue to do a good job in routine work such as daily temperature detection and killing and ventilation in public places, strengthen entry-exit management, give full play to the inspection and supervision role of discipline inspection team, ensure the implementation of epidemic prevention and control, give full play to the awareness of owners, bring outsourcing units into the "integrated" management of epidemic prevention and control, increase publicity and guidance, and enhance the awareness of prevention and control of all staff.

Carry out normalization of epidemic prevention and control

Plan ahead to promote project construction. After the outbreak of the epidemic, how to minimize the adverse impact of the epidemic and ensure the project construction progress is the main issue considered by the company. The leaders of the joint stock company are also worried. On the fifth day of the year, they contacted the headquarters of the construction unit in China to coordinate domestic construction personnel to speed up the progress of entering Thailand, and more than 50 construction personnel arrived at the site before Thailand was "sealed off", It has greatly guaranteed the construction progress of the on-site project and laid a solid foundation for the smooth progress of the project. At the same time, on the premise of paying close attention to epidemic prevention and control, the company, based on the principle of "stabilizing people's hearts and stabilizing in the local area", 19 project team members on the site have worked continuously for more than one year. At the same time, they try to stabilize the construction personnel locally, work overtime to seize the construction period, and complete the internal closing work of main plants such as extrusion workshop and spraying workshop on time, At the same time, the installation and commissioning of 115kv substation were successfully completed, the substation was officially powered on June 25, 2019, and the LNG gas station was officially powered on September 15, 2019, realizing both hands in epidemic prevention and control and project promotion.

The construction of each sub project was carried out in an orderly manner

Seize every minute to ensure that the equipment is in place. The sudden outbreak of COVID-19, which swept the globe, has a great impact on international logistics. In order to rush ahead with the progress of equipment delivery, the leaders of the stock company personally butted the equipment manufacturers and urged the delivery arrangements many times. Before the shipping fees rose in June, all the equipment and steel structures were shipped (the freight rate rose more than 5 times in November that year), effectively avoiding the risk of increasing logistics costs. It provides strong support for the overall project construction progress.

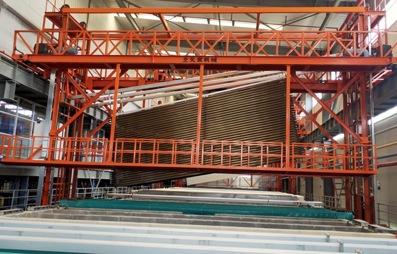

We don't have to pay close attention to equipment commissioning. After the arrival of the equipment, the installation and commissioning personnel of the manufacturer failed to arrive in time due to the impact of epidemic control. In order to catch the progress of equipment installation and commissioning, all members of the project team went to the battle to install and debug the extrusion and spraying production line. After working overtime for more than one month, the linkage commissioning of the whole spraying line was completed by the end of September 2020, and the two oxidation lines have production capacity. On September 30, the production of the first batch of spraying qualified aluminum materials was successfully realized, and the production and supply guarantee of the first batch of export orders of 8 tons of spraying aluminum materials was completed in early December, realizing a breakthrough in the export orders of the company's aluminum products. At present, the company has produced 345 tons of extruded aluminum and 261 tons of sprayed aluminum, and has developed many series of sprayed aluminum, such as 90a, 95, 93, 101, 46, 37, louver and so on.

Installation and commissioning of extrusion production line

The first spray product is released

Complete the production and supply guarantee of 8 tons of sprayed aluminum in the first batch of export orders

Clench your teeth to ensure the commissioning on schedule. Since April of this year, the third wave of COVID-19 in Thailand has erupted and rapidly spread to the whole territory of Thailand. The epidemic situation around the park has been further aggravated, and the company is also in the critical stage of the transition from infrastructure to trial production. In the face of the complex and changeable external situation, the company strictly implements the epidemic prevention and control requirements of the group and joint stock companies, combined with the actual situation in Thailand. Strengthen targeted epidemic control to ensure the physical and mental health of employees, and orderly promote the commissioning and installation of casting, oxidation and auxiliary equipment. At the end of August, the installation of melting and casting, oxidation and auxiliary equipment was completed, the single point commissioning of melting and casting equipment was completed on September 10, and the linkage commissioning of oxidation equipment was completed on September 15. On September 16, the oxidation production line realized the linkage operation of the whole line, and successfully produced four products: silver oxide white, black, bronze and champagne oxide coloring materials. The oxidation production line was officially put into trial operation. At present, the equipment in the melting and casting process has been installed. Considering safety risks and other factors, after the technicians with mature experience arrive, speed up the work related to furnace drying and trial production, further reduce the raw material cost and improve the operation efficiency of the company.

Champagne colored aluminum oxidation coloring is completed

Installation and commissioning of casting line

The wind is strong and the tide is surging. You should set sail and break the waves. There is a heavy task and a long way to go. You need to ride a horse and whip. One belt, one road, is still in a critical situation in Thailand. The global economic and trade recovery is not fast enough. The external situation is further increasing. But it is only difficult that it will show more courage. As a pioneer company in Thailand, the company will take the lead in "one belt and one Road" overseas development, and will have stronger confidence and more vigorous morale under the firm leadership of the group and the joint stock company. We should be more enthusiastic and pragmatic, strengthen the responsibility, take the initiative, quickly adjust the work direction, accelerate the expansion of the international market, straighten out the internal management process, strive to improve the company's efficiency and open a new chapter in the international development of the joint-stock company on the premise of doing a good job in epidemic prevention and control!